Advanced Liquid Nitrogen Cooling for Thermal Analysis Instruments

Thermal analysis instruments, including Thermomechanical Analyzers (TMA), Differential Scanning Calorimeters (DSC), Dynamic Mechanical Analyzers (DMA), and Differential Thermal Analyzers (DTA), often require precise temperature control across wide ranges to deliver accurate measurements. Many applications demand sub-ambient temperatures as low as -150°C or even lower, making liquid nitrogen (LN2) cooling essential for comprehensive material characterization

Why Liquid Nitrogen Cooling is Critical for Thermal Analysis

- – Extended Temperature Ranges: Modern thermal analysis requires temperature ranges that span from cryogenic conditions (-150°C to -180°C) up to elevated temperatures (600°C to 1000°C+). LN2 cooling enables instruments to access these critical low-temperature regions where many materials exhibit significant property changes including glass transitions, crystallization events, and thermal expansion characteristics.

- – Enhanced Measurement Capabilities: Sub-ambient cooling allows researchers to study temperature-dependent material properties that are impossible to observe at room temperature. This includes precise determination of glass transition temperatures (Tg), coefficient of linear thermal expansion (CLTE), thermal stress analysis, and dynamic mechanical properties across extended temperature ranges.

- – Improved Data Quality: Controlled cooling rates and stable low temperatures are essential for accurate baseline performance and precise measurement of dimensional changes, heat flow, and mechanical properties. LN2 cooling provides the rapid cooling rates and temperature stability required for high-quality thermal analysis data.

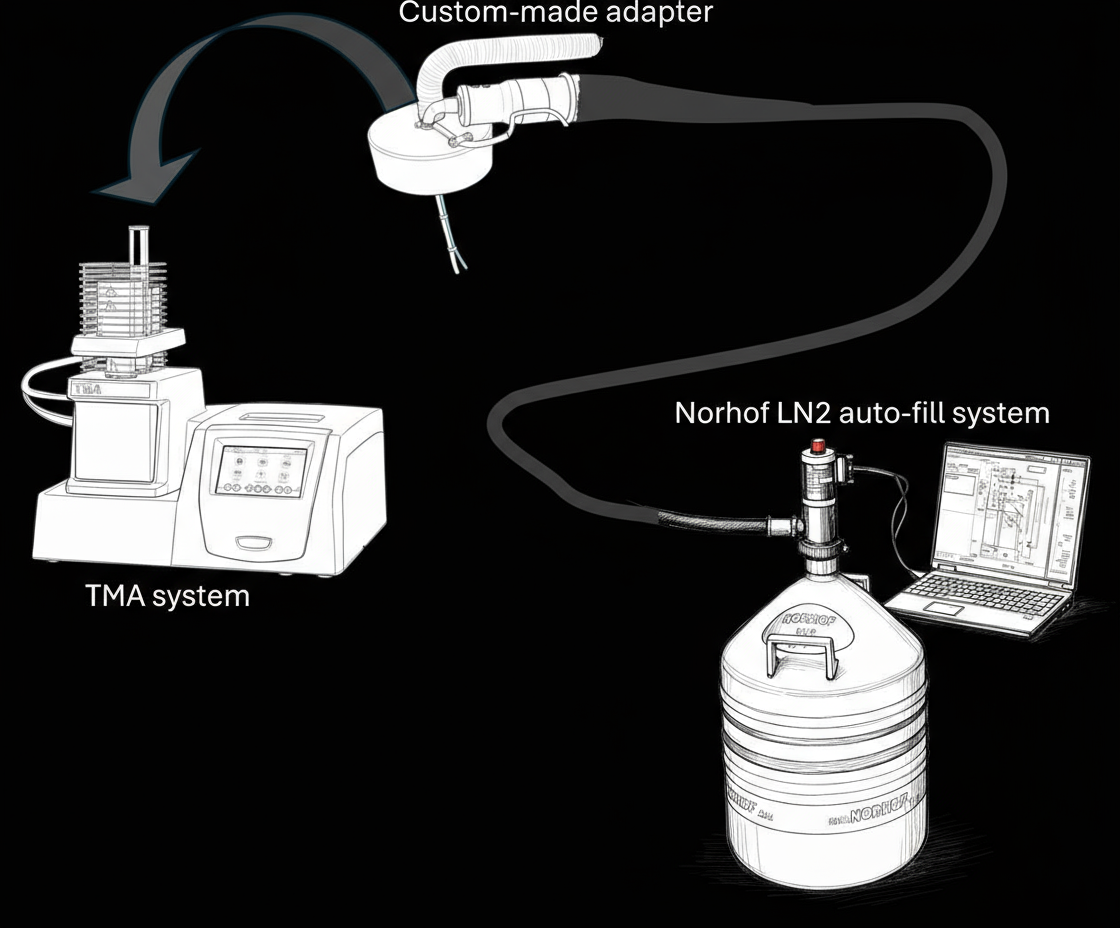

Norhof LN2 Auto-Fill System Advantages

- – Safe & automated: No direct contact with LN2, fully automated filling—ideal for overnight runs and long measurements.

-

– Pressure-free design: Maximum pressure only 300 mBar, quiet operation without vibration or noise.

-

– Precise flow control: Adjustable from a few drops up to 0.5 L/min; easily configured via software or external control for any instrument.

-

– No ice formation: Internal evaporation prevents line blockages from ice.

- – Always ready: System is on standby day and night for scheduled and on-demand cooling tasks.

Custom Adapters for Leading Thermal Analysis Brands

Universal Brand Compatibility: Norhof designs and manufactures custom-made adapters specifically engineered for thermal analyzers from all major manufacturers. Our extensive experience includes seamless integration with instruments from:

-

– TA Instruments

-

– NETZSCH

-

– METTLER TOLEDO

-

– Shimadzu

-

– Hitachi High-Tech

-

– PerkinElmer

-

– Linseis

-

– Rigaku

Precision Engineering: Each custom adapter is precisely manufactured to ensure optimal fit, proper sealing, and efficient LN2 delivery to the specific cooling chamber or detector design of your thermal analyzer. Our engineering team works closely with instrument specifications to guarantee perfect integration without compromising measurement accuracy or system performance.

Conclusion

The Norhof LN2 auto-fill system transforms thermal analysis capabilities by providing safe, reliable, and efficient liquid nitrogen cooling with custom-engineered adapters for every major thermal analyzer brand. By eliminating manual handling risks, reducing operator workload, and ensuring consistent low-temperature performance across all leading instrument manufacturers, these systems enable laboratories to achieve more comprehensive material characterization while improving both safety and productivity. Whether for routine quality control or advanced research applications, Norhof’s proven technology and custom adapter solutions deliver the precise cryogenic cooling that modern thermal analysis demands.