Recently, we had the opportunity to visit the laboratory of Mr. Arnold van Dijk at the Geolab of the faculty of Geosciences, Utrecht University. Here, we gained valuable insights into the lab’s daily work conducting highly precise carbonate analyses, in which the Norhof #905 LN2 auto-fill system plays a central role.

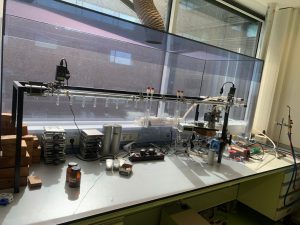

At Utrecht, the Norhof #905 is integrated into a Thermo Kiel IV Carbonate Device, which is connected to a Thermo 253 Plus mass spectrometer for isotope analysis.

The workflow is fully automated: samples are picked up and reacted with acid inside a heated (70ºC) sample chamber to speed up the reaction. This releases water and CO₂, which is then purified via a series of three cold traps:

- – First cold trap (-196°C): Efficiently removes water from the sample.

- – Intermediate trap (-40°C, custom-built with a heater, designed in Zurich, by ETH): Contains Porapak to absorb organic contaminants.

- – Final cold trap (-196°C): Re-purifies the CO₂, ensuring the highest purity before it enters the Thermo 253 Plus for analysis.

The Norhof #905 LN2 auto-fill system, equipped with two level sensors, ensures that all cold traps remain at the proper level of liquid nitrogen for the entire 1.5-day analytical run. The advantages? Minimal nitrogen consumption due to the system’s high efficiency, no unnecessary LN2 losses as can occur with manual or high-pressure systems, and reliable, continuous operation—a must for long, precise analyses.

According to Arnold van Dijk, the Norhof system has become indispensable in the lab. The user experience since 2005 has been outstanding: reliability, efficiency, and ease-of-use are at the forefront. The importance of such a stable cooling solution is highlighted when one considers how sample prep used to be performed: manual vacuuming, acid addition, and topping up cold traps—by hand—leading to higher risk of errors and reduced reproducibility.

At present, the analysis process is fully automated. Samples are prepared and measured without any compromise in precision or convenience—enabled in part by the quiet reliability of the Norhof LN₂ auto‑fill system. For us as the supplier, it is inspiring to observe how our technology contributes to advanced, internationally oriented scientific research.

Contact us for all your questions