Norhof LN2 microdosing systems

The reservoir Dewar can safely stand next to your working place, ready for use. The #606 pump when switched ON, starts building a small over-pressure, forcing the liquid gently to rise into the fill line and fall into your dry DSC reservoir. The sensor, placed also in the reservoir, makes the filling slower when for example 4 cm level is reached. If the level becomes lower, filling is increased. If the level becomes too high, filling is slower, thus keeping the level continuous on 4 cm.

The Norhof LN2 microdosing system is designed to overcome the drawbacks of LN2 under pressure in which a solenoid valve is used to switch the supply ON / OFF. You may compare the Norhof system with a water tap, but instead of giving water, it gently gives liquid nitrogen, with an adjustable flow, possible to regulate from some drops, up to 1 liter/minute. Our pump can pump LN2 up to 4 meters above the pump itself

Working principle

The pressure above the liquid level inside the Dewar is built by heating a small amount of liquid in the bottom of the Dewar. With only up to 100 mBar of over-pressure, the liquid will gentle rise out of the rise pipe and fall into the fill hose. Because we evaporate some LN2 to build pressure, there is no adding of ice inside the Dewar, such as with manual systems which use air from the environment.

The pressure above the liquid level inside the Dewar is built by heating a small amount of liquid in the bottom of the Dewar. With only up to 100 mBar of over-pressure, the liquid will gentle rise out of the rise pipe and fall into the fill hose. Because we evaporate some LN2 to build pressure, there is no adding of ice inside the Dewar, such as with manual systems which use air from the environment.

When LN2 is required, a small overpressure is generated by a small heater element in the LN2, and liquid flows out of the system like water from a tap, without spilling, noise, vibrations etc.

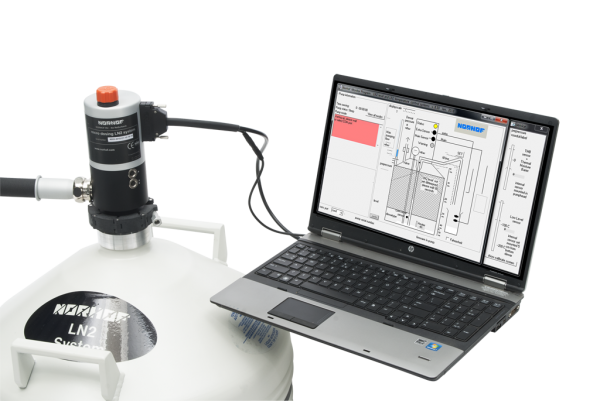

Software

To display sensor temperatures, vessel pressure, status of LED’s on the pump etc. our Norhof Monitoring software is included with any #606 series pump. This software works under Windows ’98 – 2000 – ME – NT – Vista – W7 – Windows 10 – Windows 11