900 series applications

Over the years we encountered various applications for LN2 cooling and came to realize that cooling applications can generally be divided in level control and temperature controlled applications:

Level controlled applications (#905 pump):

– filling cold traps in vacuum systems;

– filling biological storage vessels;

– filling various small vessels one after the other at the press of a button;

– filling actions at timer set intervals;

– maintaining a certain level around 1 sensor;

– maintaining a level between 2 sensors.

In this kind of applications a system is used to transfer liquid from the storage vessel to the application at a given rate, until a sensor or other signal (e.g. switch or timer) stops the flow. This implies “on-off” control of the liquid flow, this with a flow which can be extremely gentle if necessary.

Temperature controlled applications (#910 and #915 pump):

– thermal analysis systems;

– computer controlled freezing;

– gas chromatography;

– temperature stages in microscopes;

– sub-zero temperature control systems;

– stopping chemical reactions;

– cooling of targets, IR cells, cuvettes etc.

In these applications a system is used in a micro-dosing way to bring just enough “cold” to the application as is needed, more at first to achieve the required sub-zero temperature and later less to maintain the temperature. This implies flow control in an analogue fashion of “more-less” based on temperature measurement.

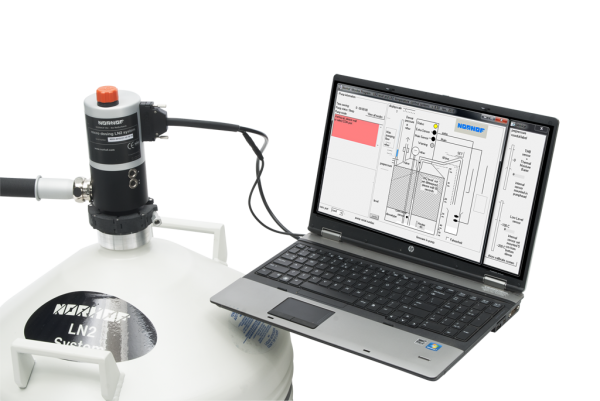

Each system is designed to be truly universal. It’s various built-in modes of operation is of paramount importance for OEM and research applications as one system covers almost all possible needs for cooling, without the need for additional valves, control instruments etc. This means that standardisation within the facility is no longer wishful thinking, despite the various applications.

For any system a host of control possibilities are foreseen. This makes it possible to control a system from existing analytical equipment, PLC’s, simple switches, computers etc. almost without any adaptations.

900 series working modes explanation

On the PCB in the pump, under the cap, is a 16-position switch to select the working mode. This working mode determines how the pump reacts on the sensor, button, RS232 signals, etc.

Each working mode is designed for a specific function.

You must select a working mode (only once) to let the working correspond with your application.